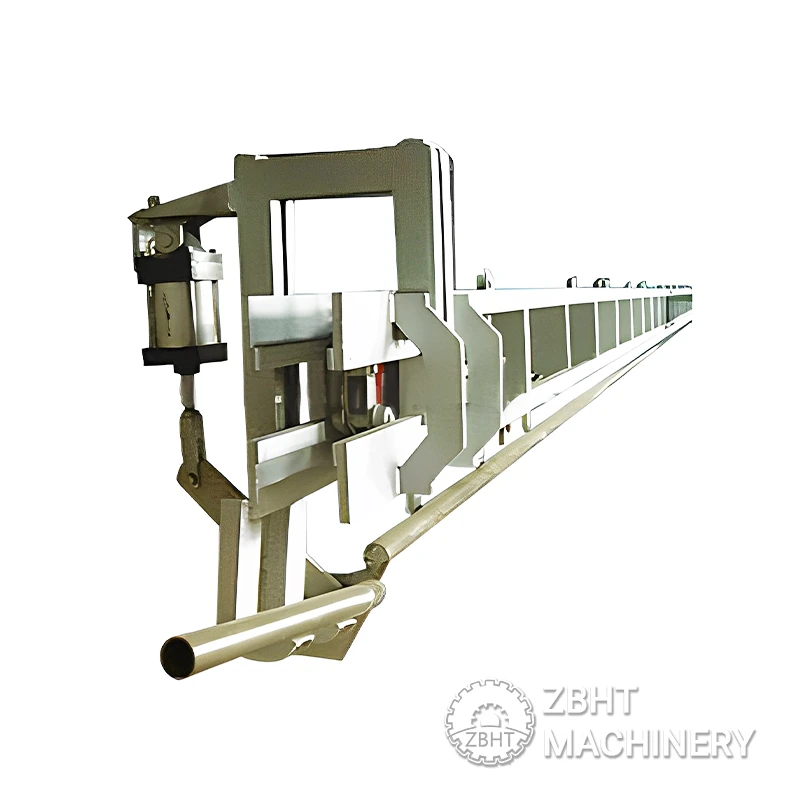

The carcass processing conveyor is the conveying equipment on the automatic line of cow slaughter equipment. The equipment uses automatic PLC control so that the mechanical transmission system and the pneumatic transmission work together. It adopts station control and can use five stations, seven stations, and nine stations according to the output to meet different requirements. On the carcass processing conveyor, it is necessary to complete the processes of cutting the head, tying the esophagus, opening the chest, taking the white viscera, taking the red viscera, splitting in half, carcass inspection, and carcass trimming. Carcass processing conveyors can also be used in sheep and horse slaughtering lines.

The cow carcass conveyor adopts the PLC central control system to control the frequency converter of each conveyor line, and automatically adjusts the speed of the driving device, so as to realize the automatic and synchronous operation of the entire slaughtering line conveying system without stopping;

Include:

-Rack hot-dip galvanizing, chain galvanizing, closed track, pipe rail adopts φ60X4 stainless steel pipe rail track

-Step-by-step, station spacing 2200mm

-The length of the conveyor is determined according to the number of stations

-Includes a set of feeding device

-Includes one and two sets of pneumatic back-off devices for chest opening, splitting, etc.

-Beef carcass spacing: 2100-2200mm,

-Synchronized with the red and white viscera quarantine conveyor line.

No. We are the original manufacturer of animal slaughtering lines, meat processing equipment, deboning and cutting system, spare parts, etc.

We have 3 slaughtering lines in our factory, including 1 cattle slaughtering line, 1 sheep slaughtering line and 1 pig slaughtering line. We also have deboning and cutting systems, hygiene tools, etc in our factory. You can also see the different design in our sample line room.

Normally, we will need 3 weeks for single machine, and 2 months for a whole production line. For confirmation, we will need to confirm with production director first. However, we will make your production lines as soon as possible.

We will need 30% of total contract value in advance by T/T as deposit. And the balance will be paid before your products are shipped out of factory.

We have our own inspection team in factory. They will inspect the raw material, semi-finished product, finished product following our drawing and standard in quotation sheet. You will get what you see during factory visit and you can check your products during the production anytime during the production.

Yes. We will send 1 engineer for overseas project guiding installation. As a buyer, you will need to pay for the round way air tickets, food and accommodation, local transportation in your project location, and also pay the allowance of the technician during installation.