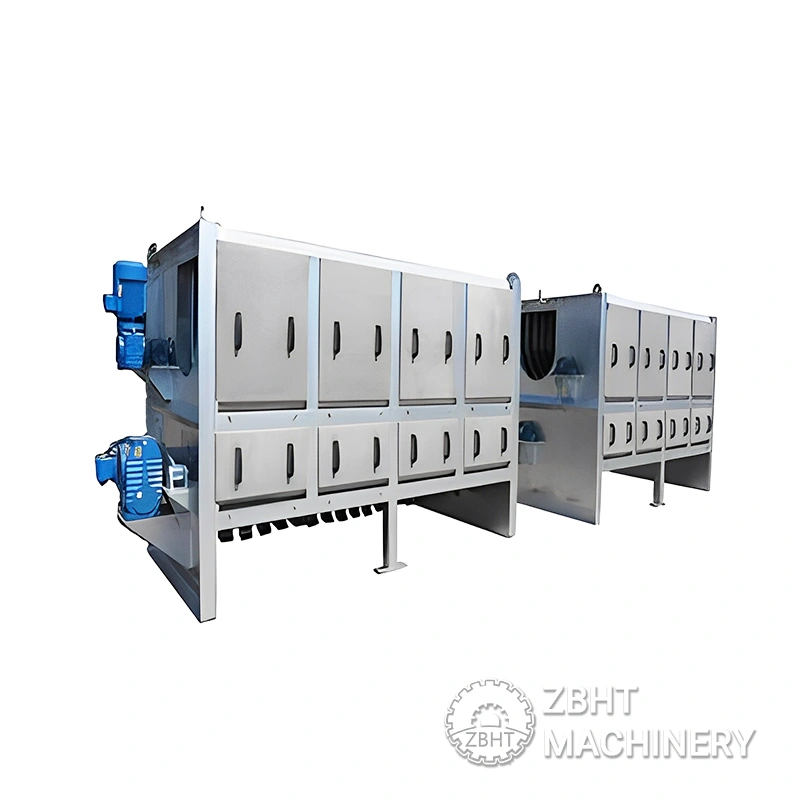

A continuous hog dehairer machine is a special dehairing equipment for pigs, suitable for dehairing operations in large and medium-sized pig slaughtering and processing production lines. It has the advantages of convenient operation, high bearing capacity, and high hair removal rate. It is connected with tunnel steam scalding equipment.

| Rated voltage | 380Vac |

| Power | 11kw+7.5kw |

| Output | 250–350 heads/hour |

| Maximum load | 150KG |

| Size | 3300*1800*2200mm |

The reducer drives the two shaving rollers to rotate, so that the pig body in the tunnel rolls quickly, and the pig body, the shaving sheet and the U-shaped plate move and rub against each other, so as to achieve the purpose of shaving. During the process of shaving, the pig body gradually moves toward the outlet spirally, and finally slides out automatically, realizing continuous automatic operation. Usually, two dehairing machines are used in series, one rotates clockwise, and the other rotates counterclockwise, so as to achieve a satisfactory dehairing effect.

The rubber shavings are vulnerable parts, and should be replaced immediately after damage, so as not to affect the shaving effect.

No. We are the original manufacturer of animal slaughtering lines, meat processing equipment, deboning and cutting system, spare parts, etc.

We have 3 slaughtering lines in our factory, including 1 cattle slaughtering line, 1 sheep slaughtering line and 1 pig slaughtering line. We also have deboning and cutting systems, hygiene tools, etc in our factory. You can also see the different design in our sample line room.

Normally, we will need 3 weeks for single machine, and 2 months for a whole production line. For confirmation, we will need to confirm with production director first. However, we will make your production lines as soon as possible.

We will need 30% of total contract value in advance by T/T as deposit. And the balance will be paid before your products are shipped out of factory.

We have our own inspection team in factory. They will inspect the raw material, semi-finished product, finished product following our drawing and standard in quotation sheet. You will get what you see during factory visit and you can check your products during the production anytime during the production.

Yes. We will send 1 engineer for overseas project guiding installation. As a buyer, you will need to pay for the round way air tickets, food and accommodation, local transportation in your project location, and also pay the allowance of the technician during installation.