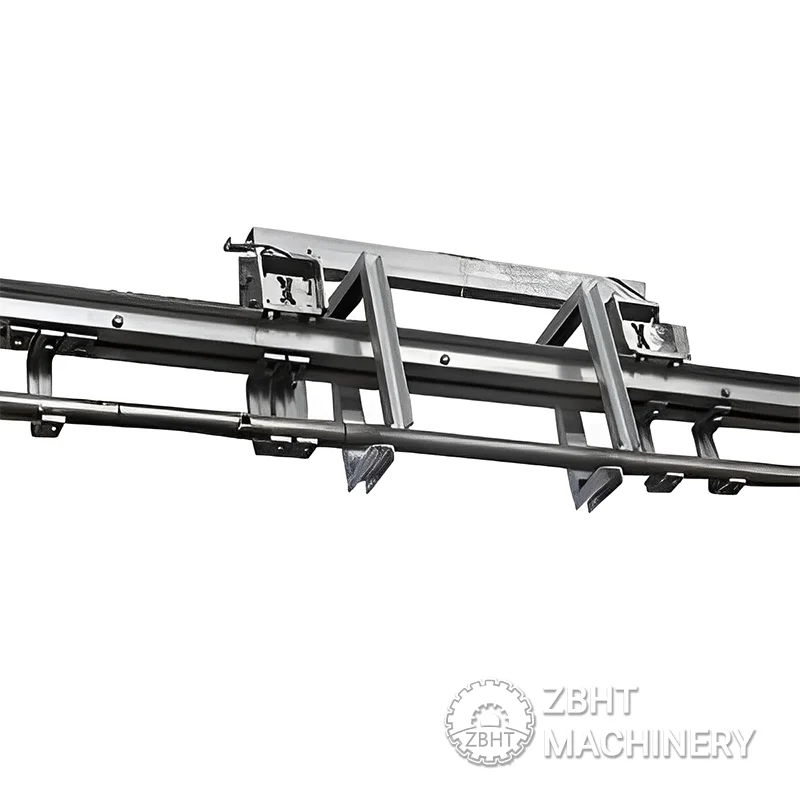

The slaughtering electronic scale is a device mounted on a sliding track, which is specially used in pig, cattle, and sheep slaughterhouses. When weighing, it is only necessary to swipe on it to accurately weigh the weight. It has the function of waterproof and moisture-proof, which effectively overcomes the characteristics of large moisture in the slaughter workshop. Multiple hooks can be used to improve work efficiency; the number of weighing heads is different each time, and the number of hooks is peeled once in place; it is widely used in the weighing of pork, mutton, beef, and other slaughtering industries.

It is mainly composed of sensors, meters, junction boxes, and mechanical parts. Since there is a lot of moisture in the slaughtering workshop and the moisture is too heavy, waterproofing is generally required.

Since this kind of electronic scale is directly installed on the sliding track of the slaughterhouse, it can be automatically weighed by gently sliding over the weighing area during weighing, and the meat can be unloaded for weighing, thereby greatly reducing the labor intensity of the staff. It is the electronic metering equipment of the majority of slaughterhouses to improve work efficiency.

1. The price is affordable, which is more cost-effective than traditional electronic water platform scales.

2. The measurement is convenient, the work procedure is reduced, and the labor efficiency is improved.

3. Accurate measurement, the real standard of a three-level scale (industrial and commercial trade settlement).

4. The failure rate is low. Because it is installed on the track, the weighing is automatically measured during normal work, avoiding the operation of the staff, and the sensor of the slaughtering scale is better than that of the ordinary platform scale, so the failure rate is greatly reduced.

5. It can greatly improve work efficiency. Since the electronic scale is installed on the sliding track of the slaughtering scale, the ordinary slaughtering scale can weigh three pigs at the same time. It greatly increases the delivery rate.

The electronic scale is a precision instrument. When using it, try to have a special person responsible to check whether the orbital weighing area deviates from the main road and whether the mechanical parts are firm, and correct it regularly.

-0.5 tons,

-Includes printer and monitor

Including 800mm long guide rail

No. We are the original manufacturer of animal slaughtering lines, meat processing equipment, deboning and cutting system, spare parts, etc.

We have 3 slaughtering lines in our factory, including 1 cattle slaughtering line, 1 sheep slaughtering line and 1 pig slaughtering line. We also have deboning and cutting systems, hygiene tools, etc in our factory. You can also see the different design in our sample line room.

Normally, we will need 3 weeks for single machine, and 2 months for a whole production line. For confirmation, we will need to confirm with production director first. However, we will make your production lines as soon as possible.

We will need 30% of total contract value in advance by T/T as deposit. And the balance will be paid before your products are shipped out of factory.

We have our own inspection team in factory. They will inspect the raw material, semi-finished product, finished product following our drawing and standard in quotation sheet. You will get what you see during factory visit and you can check your products during the production anytime during the production.

Yes. We will send 1 engineer for overseas project guiding installation. As a buyer, you will need to pay for the round way air tickets, food and accommodation, local transportation in your project location, and also pay the allowance of the technician during installation.