The cattle splitting saw is special slaughter equipment to split the carcass in half operation with the closed band saw as the working part.

This device is mainly used for the cattle carcass splitting process. It can also be used for pig, cattle, and sheep/goat carcass splitting.

This saw blade will move in the middle of the spine and cut cattle carcasses into two average parts.

| Voltage | 380/220V |

| Dimension(L*W*H) | 1500*400*580mm |

| Weight | 120KG |

| Motor power | 2.2KW |

1. Turn on the power switch, lift the front end of the saw, aim at the middle of the spine of the carcass and start the operation;

2. After sawing into the carcass, the operator should hold on to the sawing body steadily, with even force, and do not stop until the split is completed.

1. When splitting the saw should be placed smoothly, the saw blade shall not be knocked against by any hard object;

2. Do not offset the saw body when splitting, so as not to break the saw blade;

3. Do not operate when water is scarce.

1. Waterproof touch switch, fully enclosed design;

2. Water spraying device, cleaning continuously in use, cooling saw blade;

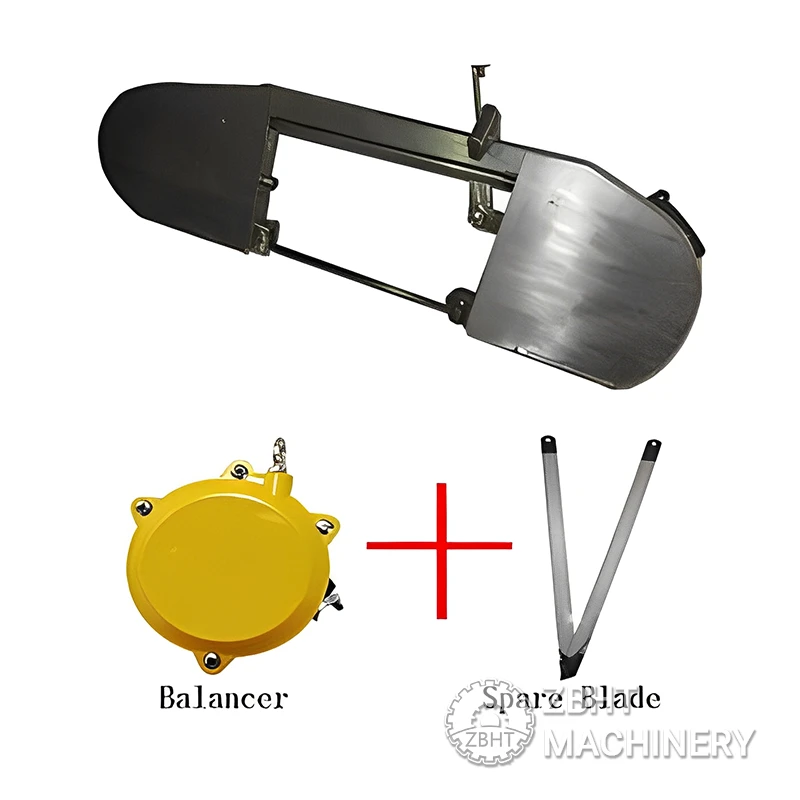

3. Used together with the balancer to reduce labor intensity;

4. Low voltage operation, safe and reliable;

5. Convenient and comfortable grip, no vibration.

No. We are the original manufacturer of animal slaughtering lines, meat processing equipment, deboning and cutting system, spare parts, etc.

We have 3 slaughtering lines in our factory, including 1 cattle slaughtering line, 1 sheep slaughtering line and 1 pig slaughtering line. We also have deboning and cutting systems, hygiene tools, etc in our factory. You can also see the different design in our sample line room.

Normally, we will need 3 weeks for single machine, and 2 months for a whole production line. For confirmation, we will need to confirm with production director first. However, we will make your production lines as soon as possible.

We will need 30% of total contract value in advance by T/T as deposit. And the balance will be paid before your products are shipped out of factory.

We have our own inspection team in factory. They will inspect the raw material, semi-finished product, finished product following our drawing and standard in quotation sheet. You will get what you see during factory visit and you can check your products during the production anytime during the production.

Yes. We will send 1 engineer for overseas project guiding installation. As a buyer, you will need to pay for the round way air tickets, food and accommodation, local transportation in your project location, and also pay the allowance of the technician during installation.