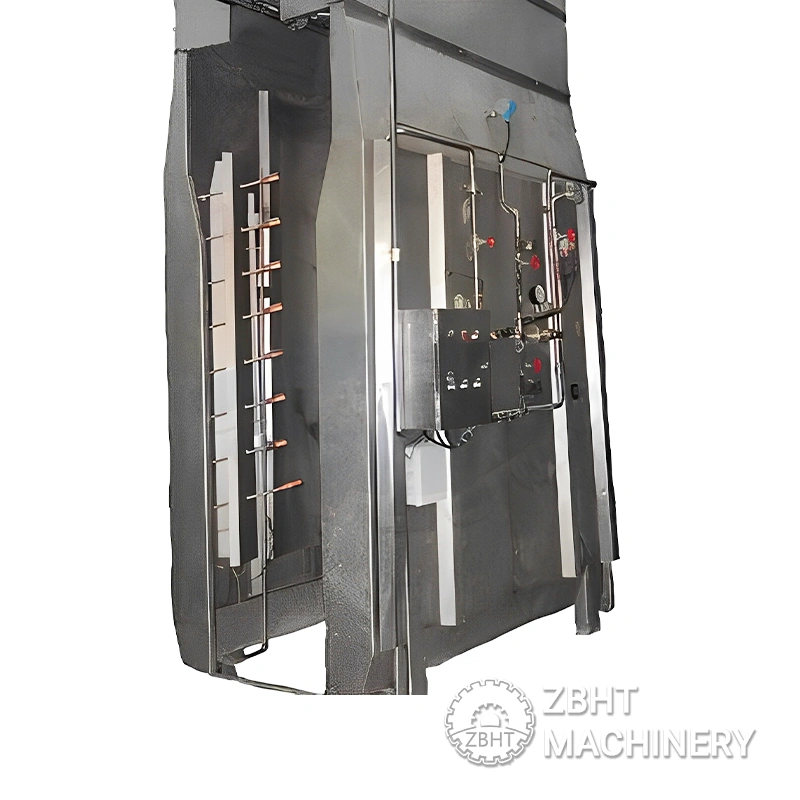

The pig singeing machine transports the pig carcass from the skinning and hair-shaping area to the pig carcass processing line to complete the processes of the scorching, trimming, and hanging residual hair.

| Conveyor line speed (adjustable) | 6~9m/min |

| PLC intelligent control program and system | |

| Liaoning time (adjustable) | 2~6/S |

| Control voltage | 24V DC |

| Gas working pressure | 0.1~0.25 MPa |

| Gas consumption | head/㎏ ≤0.18 |

| Dimensions | 2350X1260X3970mm (length X width X height) |

The pig singeing machine is controlled by PLC. When the pigs pass through the pig singeing machine, the photoelectric switch senses, and the smoldering starts automatically. The pigs pass through the smoldering furnace after 2~6s on the automatic bloodletting line. When induction occurs, the fire is stopped, and the smoldering ends.

The machine has low energy consumption, high efficiency, and a high scorching rate, which effectively improves the output.

No. We are the original manufacturer of animal slaughtering lines, meat processing equipment, deboning and cutting system, spare parts, etc.

We have 3 slaughtering lines in our factory, including 1 cattle slaughtering line, 1 sheep slaughtering line and 1 pig slaughtering line. We also have deboning and cutting systems, hygiene tools, etc in our factory. You can also see the different design in our sample line room.

Normally, we will need 3 weeks for single machine, and 2 months for a whole production line. For confirmation, we will need to confirm with production director first. However, we will make your production lines as soon as possible.

We will need 30% of total contract value in advance by T/T as deposit. And the balance will be paid before your products are shipped out of factory.

We have our own inspection team in factory. They will inspect the raw material, semi-finished product, finished product following our drawing and standard in quotation sheet. You will get what you see during factory visit and you can check your products during the production anytime during the production.

Yes. We will send 1 engineer for overseas project guiding installation. As a buyer, you will need to pay for the round way air tickets, food and accommodation, local transportation in your project location, and also pay the allowance of the technician during installation.