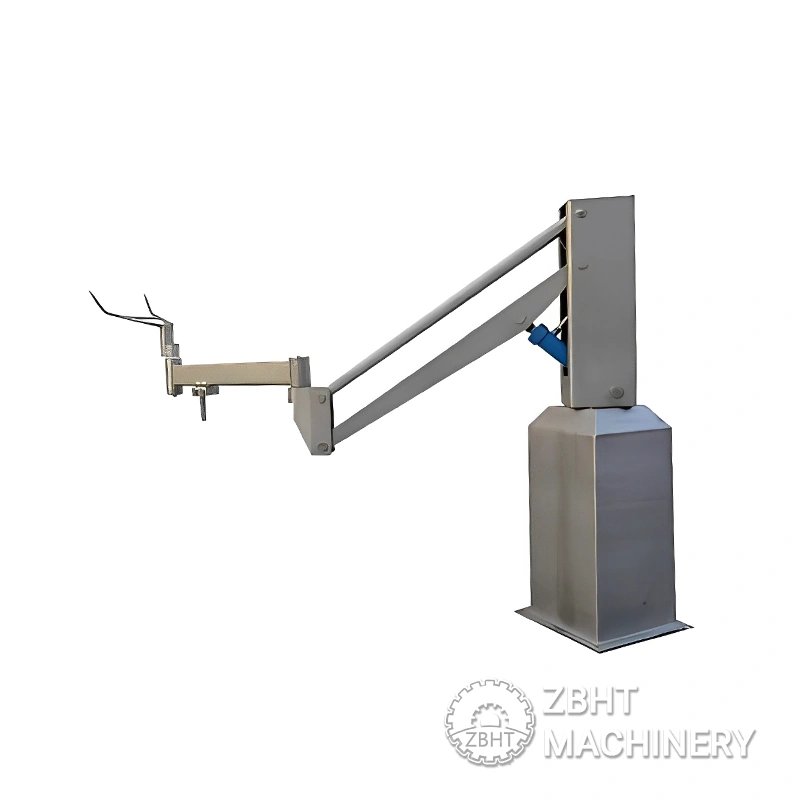

The meat loading arm is used for meat loading and unloading in cold storage and chilling room. The loading arm is simple to operate and easy to move; Simply press the button to move up, down, left, and right; Save time and labor.

| Applicable Industries | Food & Beverage Factory, Farms, Food Shop, Food & Beverage Shops, Meat processing plant |

| Voltage | 380V/220v, 220V/380V |

| Dimension(L*W*H) | 2600*500*1700mm |

| Weight | 320kg |

| Warranty | 1 Year |

| Core Components | Bearing, Motor, Pump, Gear, PLC, Engine, Gearbox |

| Name | meat loading arm |

| Motor power | 1.5kw |

| Move speed | 0.3m/s |

| Move height range | 1100-2300mm |

| Suit for | Pig/cattle slaughterhouse |

| Brand | ZBHT |

| Loading radius | 2400mm |

| Material | Stainless Steel |

| Driving method | hydraulic |

| Arm rotation | 260 |

| Head rotation | 320 |

| Total useful rotation | 350 |

| Maximum capacity | 300 kg |

* This meat loading arm is easy to operate and move, can move up, down, left, and right with the easy push of a button.

* Loading and unloading save time and labor.

* with high flexibility for various environments

* meets different daily slaughtering output

* practical with minimum cost

1. As the track height is more than 2.5m, it is difficult to manually pick it. It often happens that the hook-hanging pork falls down and injures people, which has great potential safety hazards to the operator.

2. Taking meat manually will contact the surface of the body, and the pollutants and bacteria on the body will cause secondary pollution to the meat.

No. We are the original manufacturer of animal slaughtering lines, meat processing equipment, deboning and cutting system, spare parts, etc.

We have 3 slaughtering lines in our factory, including 1 cattle slaughtering line, 1 sheep slaughtering line and 1 pig slaughtering line. We also have deboning and cutting systems, hygiene tools, etc in our factory. You can also see the different design in our sample line room.

Normally, we will need 3 weeks for single machine, and 2 months for a whole production line. For confirmation, we will need to confirm with production director first. However, we will make your production lines as soon as possible.

We will need 30% of total contract value in advance by T/T as deposit. And the balance will be paid before your products are shipped out of factory.

We have our own inspection team in factory. They will inspect the raw material, semi-finished product, finished product following our drawing and standard in quotation sheet. You will get what you see during factory visit and you can check your products during the production anytime during the production.

Yes. We will send 1 engineer for overseas project guiding installation. As a buyer, you will need to pay for the round way air tickets, food and accommodation, local transportation in your project location, and also pay the allowance of the technician during installation.