According to the different ways of skin treatment in slaughtering, pig slaughtering can be divided into two slaughter methods: pig hair removing method and pig skin removing method.

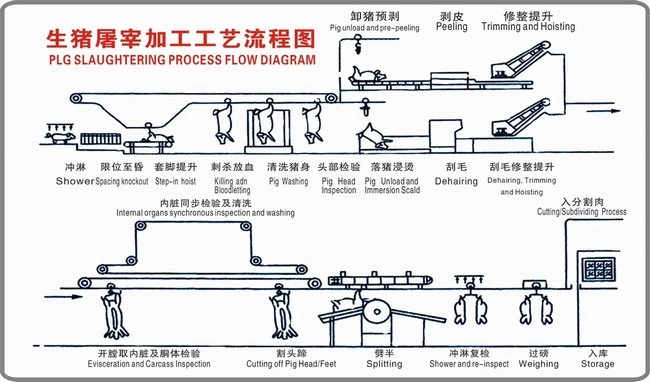

The slaughtering flow chart is introduced as follows:

1. Slaughter and processing process of pig hair removing method:

Healthy pigs enter the slaughter pen→ stop eating and stop drinking water for 12-24 hours→ shower before slaughter→ instantly stunning→ shackle the legs and lift to bleeding line→ kill the pigs → drain blood (draining time: 5 minutes) → cleaning → scalding → pig hair removing → trimming → carcass lifting→ burning hair (singeing)→ whipping→ ear trimming → sealing rectum → cutting off genitals→ brisket opening → taking out the white viscera (white viscera are placed in the tray of the white visceral quarantine conveyor for inspection, qualified viscera will enter the viscera processing room for processing, The stomach volume is transported to the waste storage room about 50 meters outside the workshop through the air conveyance system) →Trichinella inspection→ pre-pick the red offal→ take the red offal (the red offal will be hung on the hook of the red offal quarantine conveyor to be inspected, Qualified red offal is processed in the red offal processing room→ pre-cut the head→ splitting in halves→ and the simultaneous inspection of the carcass and internal organs→ removing the tail → remove head→ remove forehooves→ unqualified carcasses and viscera offal are pulled out of the slaughterhouse for high-temperature treatment → remove the hind hooves→ remove the fat→ trim the carcass→ weigh the carcass→ washing → chilling (0-4°C) → Fresh meat sales, chilled meat sales → cut into three sections → meat cuts → weighed and packaged→ quick-frozen or fresh-kept → de-plated and packed→ refrigerated→ and divided meat for sale

2. Peeling pig slaughter and processing process

Healthy pigs enter the slaughter pen→ stop eating and stop drinking water for 12-24 hours→ shower before slaughter→ instantly stunning → shackle the legs and lift to bleeding line→ kill the pigs→ drain blood (draining time: 5min) → washing of the hairy pig body → Remove the head→ unload the pig into the pre-skinning station→ remove the front and rear hooves and tail → pre-skinning → mechanical skinning → The head and tail will enter the head and tail processing room, and the processing skin is put into the pig skin temporary storage room → carcass lifting→ carcass trimming→ sealing rectum →removing genitals→ brisket cutting → take the viscera (the viscera will be placed in the viscera quarantine conveyor for inspection) → Qualified viscera enters the viscera processing room for processing. The stomach volume is transported to the waste storage room about 50 meters outside the workshop through the air conveyance system→ Trichinella inspection→ pre-pick the red offal→ take the red offal (the red offal are hung on the hook of the red offal quarantine conveyor to be inspected, qualified red offal is processed in the red offal processing room → splitting half-→ carcass, offal and viscera are inspected simultaneously (Unqualified carcasses and red and white offal are pulled out of the slaughterhouse for high-temperature treatment) → fat removal→ carcass trimming→ carcass are weighed → washing → chilling (0-4°C) → divided into three sections→ cut the meat → meat weighed and packaged and plated → Fresh meat sales or chilled meat sales → unpacked → refrigerated → split meat for sale