Slaughtering operations

1. Slaughtering process

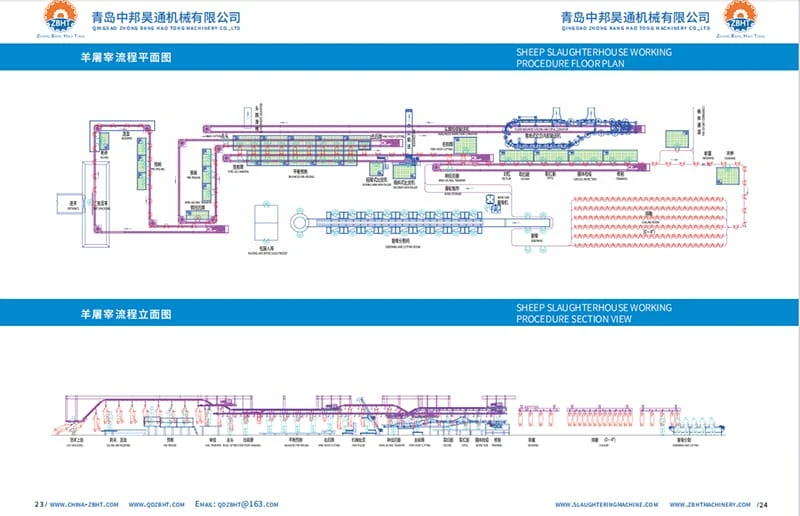

Operate according to the following slaughtering process: stunning (2) →hanging (3) →slaughtering and bloodletting (4) → peeling (5) or scalding and hair removal (6) →Head and hoof removal (7) → visceral removal (8) →carcass trimming (9) → weighing (10) → carcass cleaning (11) and by-product finishing (12).

Note: The head and hooves procedures are adjusted according to the actual process.

The operators of each process willcheck the sheep, carcasses, by-products transferred in the previous process. Products do not meet the requirements of slaughter operations, it is not allowed to transfer to the next process. Sheep carcasses and by-products should not fall to the ground or come into contact with unclean surfaces during slaughter. Adopts hot water not lower than 82 °C to disinfect each knife for one sheep. The slaughter of sheep products for the consumption of ethnic minority consumers should respect ethnic minorities customs and customs, and shall be implemented in accordance with relevant national regulations.

2 Stunning

2.1 Before slaughtering, the sheep should be fainted, and it is advisable to use the electric stunning method to make the sheep in a coma.

2.2 When using electric stunning, parameters such as voltage, current and fainting time should be appropriately adjusted according to the breed and specifications of sheep.

2.3 The electro stunning equipment should maintain good electrical contact, monitor the fainting parameters and keep relevant records.

3. Hanging

Hang the sheep's hind hooves on the track chain hooks and lift them at a uniform speed to the slaughter track.

4. Slaughter and bloodletting

4.1 cut from the throat of the sheep, it is advisable to cut off the three tubes (esophagus, trachea and carotid artery). The interval between coma and slaughter and bloodletting should not be more than 1 minute, the draining time should not be less than 5 minutes.

4.2 After draining blood, the subsequent operation can be carried out by peeling (5) or perming and hair removal (6).

5. Peeling

5.1 Pre-peeling

Pre-skinning can be carried out by horizontal or vertical hanging, and the pre-peeling process avoids wool contamination of sheep carcasses and damage to sheepskin, and the key points of operation are as follows:

a) Pick the crotch and peel the skin of the hind legs: circumcise the skin of the tarsal joint, separate the skin of the hind legs from the top and bottom, cut the skin horizontally along the inside of the hind legs and peel off the skin of the hind legs (or mechanically peel off), and at the same time peel off the genital skin of the crotch;

b) Cut the abdominal thoracic line: cut the skin from the crotch along the midline of the abdomen to the sciforming cartilage, preliminarily peel off the abdominal skin, then hold the skin in the middle of the sheep's chest, and use a knife along the midline of the chest to the bottom of the sheep's neck (or use a knife along the midline of the chest to the root of the inner thigh);

c) Peel the skin of the abdomen and chest: Peel off the skin on both sides of the abdomen and chest to the position of the shoulder blades;

d) Peel the skin of the front leg: Pick the skin along the midline of the toe joint of the front leg of the sheep, and peel the skin of the outer side of the front leg from the left and right sides to the position of the shoulder blade;

e) Peel the sheep's neck: Peel off the skin to both sides along the midline of the throat of the sheep's neck, and remove the thyroid gland (remove the scalded sheep in the carcass trimming process);

f) Peeling the tail: Cut the inner skin of the sheep's tail along the midline and peel off the sheep's tail skin from the left and right sides;

g) Pounding the skin: Use manual or mechanical methods to quickly beat the part between the skin and the carcass on the shoulder or buttocks to separate the skin from the sheep's body.

5.2 Skin peeling

Manual or mechanical peeling. The peeling process ensures that the skin is not cracked, there is no fat, the peeled carcass is not broken, and the fascia is intact.

The torn sheepskin is sent to the leather storage room. Here's how to rip the skin:

a) Manual skin-pulling: Tearing off the sheepskin from the back;

b) Mechanical skinning: The pre-skinned sheep carcass is transported to the skinning station, and the skinning equipment tears off the sheepskin from the back at a uniform speed.

6. Perm and hair removal

6.1 Scalding

The horns should be removed before perming. Hair ironing equipment should be used to iron hair, and it is advisable to soak and blanch in hot water at 65°C~70°C for 1.5min~2.5min (it is advisable to easily grab the wool by hand).

6.2 Hair removal

Immediately after perming, it is sent to the hair removal equipment for hair removal to avoid damaging the sheep carcass during hair removal. After hair removal, it is quickly cooled to room temperature by cold water to remove the residual hair on the sheep carcass.